Merrimac Recycled Water Treatment Plant

About the project

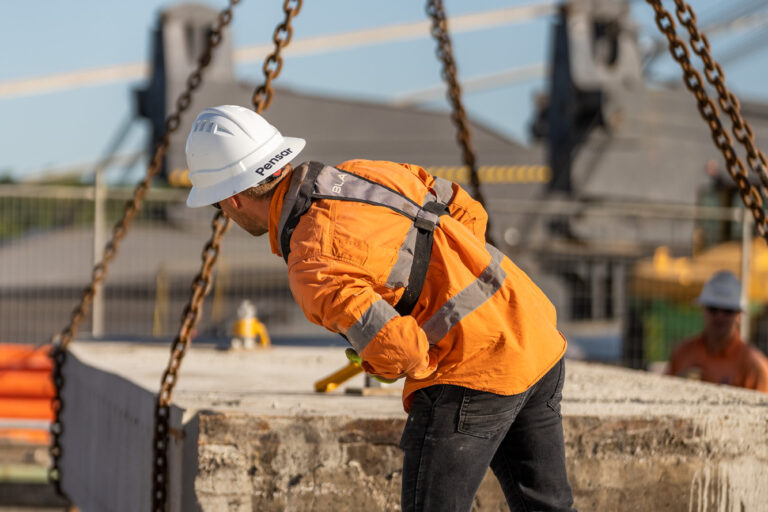

Pensar was engaged by the City of Gold Coast for the design and construction of a new 5ML/day Recycled Water Treatment Plant within the existing Merrimac Sewerage Treatment Plant.

This project was delivered utilising Pensar's multidisciplinary offering across our Water, Structures and Power capabilities.

Location

Merrimac, Queensland

Client & Duration

City of Gold Coast

August 2021 - February 2023

Project Scope

- Air-conditioned analyser building with new analysers, comms marshalling panel & process DB

- Two new concrete reservoirs (440KL & 220KL) with new roofs, access platforms, access hatches, stairway and access ladders

- Pump station and pipework to feed new RWTP

- Network pump skid

- New alum storage and dosing area

- New hypo dosing pump skid for RWTP

- Design, supply and install of new PCS cabinet & MLC board

- Dual media horizontal media filter system with UV’s, backwash & air scour systems including 30 actuated valves

- All electrical installation, testing and commissioning

- Upgrade of existing hypo dosing system for the entire STP

Challenges

- Procurement delays and price increases posed a large challenge for our team to negate with the client. This had a large impact on our Power team which resulted in some major delays to the electrical scope of works. Maintaining an open line of communication on both a project management level, as well as an executive leadership level was a crucial factor in successfully managing these items and upholding a positive working relationship.

- Our team successfully managed the PFAS contaminated material that was a latent condition, confirmed just prior to our workers mobilising on site. Pensar designed and constructed a 3000m3 HDPE lined storage area to store the contaminated materials, which was safely covered and sealed in line with all regulations and requirements.

Achievements

- Our team worked with the operators on site to minimise disruptions to daily operations. This allowed for early communications for any issues that arose, ultimately offering quick

resolutions. - Managing the design in-house provided cost and time savings for our client, but also offered more control over final design outcomes.

- The project team was able to work collaboratively to achieve both cost and time savings through the following activities and/or initiatives including procuring stainless steel pipework early and directly via overseas contacts, proposing a simpler actuated valve for the project, a program revision that resulted in the underground pipe install and concrete reservoir construction occurring simultaneously and negotiating discounts for a number of frequently used materials.