Luggage Point WWTP Bioreactors Upgrade

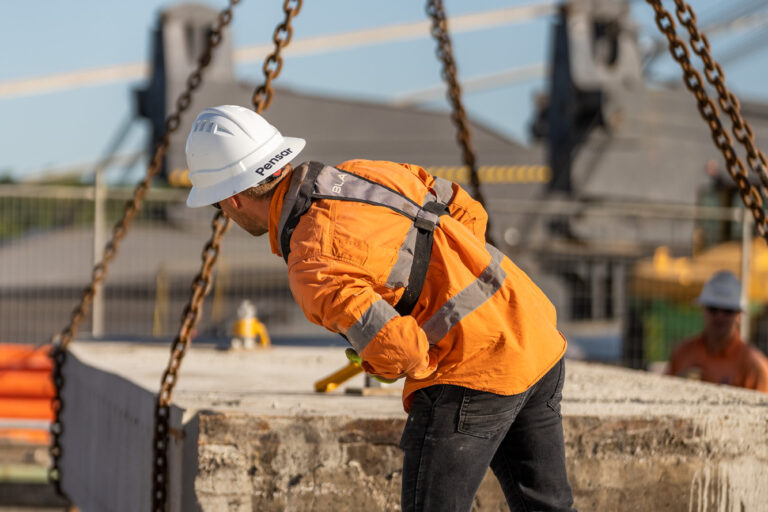

About the project

Pensar recently completed the control system upgrades of six bioreactors at the Luggage Point Resource Recovery Centre for Urban Utilities. The upgrade secured the automation of the Post Anoxic Aeration Zone (PAAZ) enabling the bioreactors to operate in either aerobic or anoxic mode based on the ammonia concentration measured by the analysers.

This upgrade will allow Urban Utilities to manage ammonia more efficiently, and reduce ammonia concentrations in the treated effluent. It will also have a positive impact on the Western Corridor Recycled Water (WCRW) scheme, which benefits from effluent with lower nutrient concentrations.

Location

Luggage Point, Queensland

Client & Duration

Urban Utilities

July 2022 - May 2023

Project Scope

- Installed new flow meters, actuators, positioners, and differential pressure indicating transmitters in PAAZ in six bioreactors

- Detailed mechanical , process, electrical and control systems design

- Design, supply, installation and commissioning of the new instrumentation for each bioreactor

- Design, supply, installation and commissioning of PLC and SCADA programming necessary to control and monitor the aeration control valve and mixers with relevant interlocks

Challenges

- The works took place on an operational site and the bioreactors were functional throughout the project. This required significant coordination with the site operations team to plan and implement each stage. There were zero issues throughout the construction and commissioning period

- The air supply in the main aeration header could not be turned off due to the failure of the existing butterfly valves upstream of our flow meter tie in point. To proceed, the blowers had to be turned off, ceasing aeration throughout all zones of the bioreactor. This presented a risk of high ammonia concentration in the treated effluent. In conjunction with the Urban Utilities team, it was decided to implement a flow control plan at the Eagle Farm Pump Station to completely halt the incoming flow to site and perform the required works during a night shift

Achievements

- During high ammonia events, the aeration in PAAZ will automatically turn on. Once the ammonia concentration drops below the setpoint, the zone automatically switches to anoxic mode where the aeration is stopped, and mixers are turned on.

- A purging mode is also incorporated that will ensure the diffusers are cleaned regularly to reduce fouling. During purging, if the differential pressure across the diffusers exceeds a certain value, a formic acid clean in place (CIP) will be enabled to enhance diffuser cleaning process

- Additionally, ammonia-based aeration ensures the zones are only aerated during high ammonia events and not 24/7, in doing so, saving energy costs