LWIA Reservoir Renewals Project

About the project

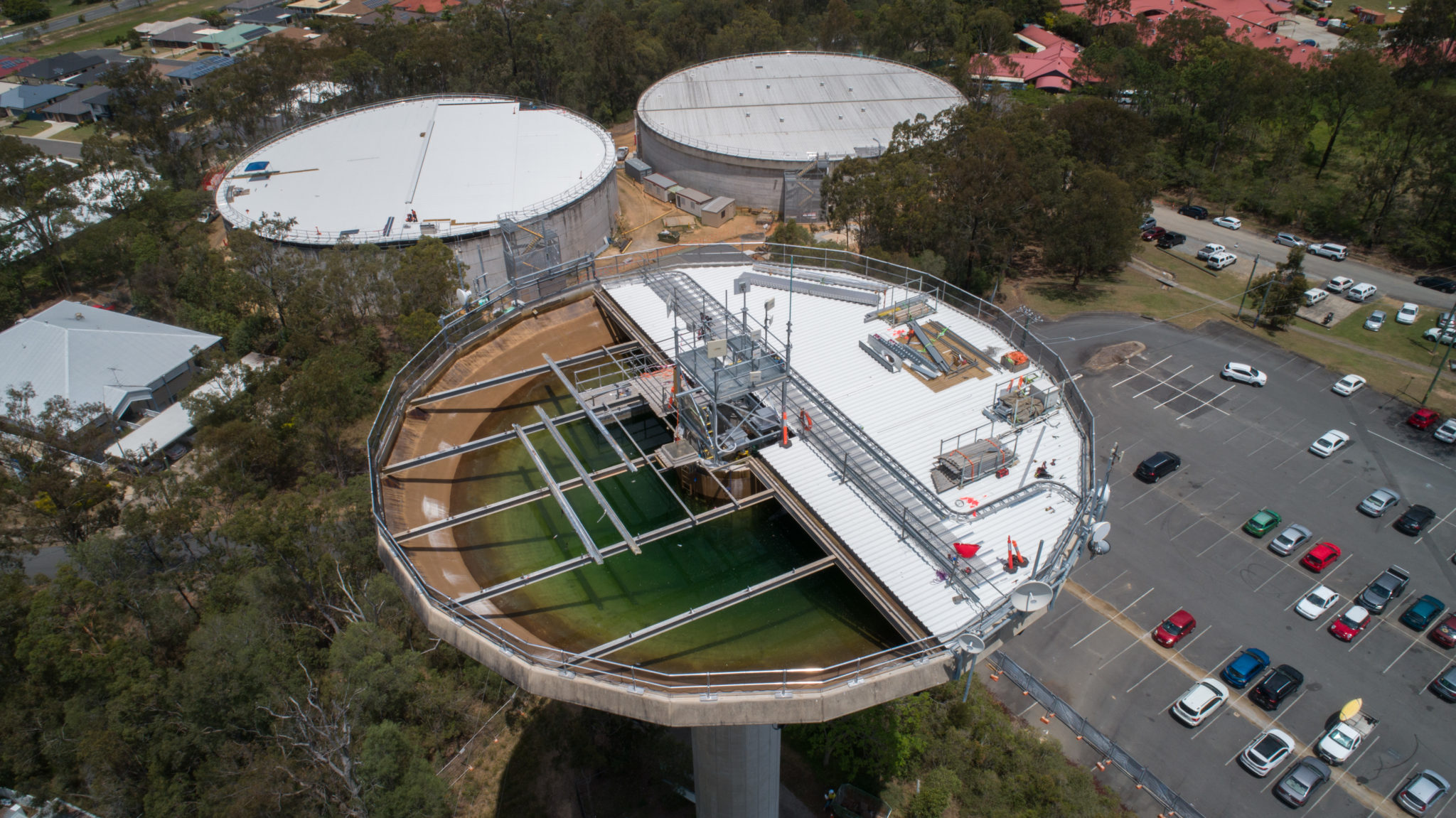

The rehabilitation works at Greenbank Reservoir were part of the Logan Water Infrastructure Alliance's (LoganWIA) Reservoir Renewals project, which involved the remediation and refurbishment of three reservoir sites across South-East Queensland. The Greenbank site involved the rehabilitation of the existing water reservoir infrastructure consisting of two low level reservoirs and one elevated tower reservoir. The purpose of the project was to improve the water quality, maintain head pressure, and ensure the assets were future proofed.

Location

Greenbank, QLD

Client & Duration

Logan Water Infrastructure Association

January 2018 - December 2018

Project Scope

- Removal and recycling of the existing roof structures of Reservoir #2 and the Wineglass

- Design and construction of new structural steel roofs, including ventilation

- Design and installation of ladders, access and telemetry hatches for operator safety

- Installation of asphalt access tracks and concrete pavements

- Preparation and installation of high-tech polyurea water-proof floor coating

- Design and construction of central antennae tower for future use by 'telcos'

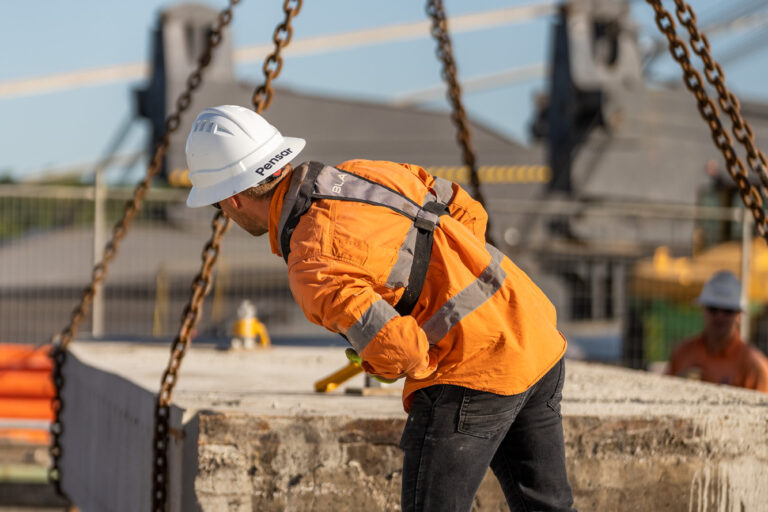

Challenges

- Works were to be completed 40m above ground level

- Safely gaining access to the roofs

- Undertaking demolition and construction at heights

- Working efficiently, due to limited storage, manoeuvring and working space

- Establishing a working platform over water

- The compressed timeframe for the overall program of works being performed at multiple sites presented an additional challenge

Achievements

- Reduced cost, time and risk, by retaining the water in the reservoir and hoisting two 3m x 3m floating pontoons to serve as a work platform

- Demolished and constructed half the roof at a time to maintain a safe storage and work area throughout

- Scheduled permanent guardrail installation up front to maximise work area and improve safety

- Designed and installed sliding joint structure within Reservoir #1 to prevent shearing - this out of scope task did not impact the original schedule

- Used advanced 3D scanning technology in the design phase to ensure manufactured components fit precisely - this eliminated rework and schedule delays

- Pensar's multi-disciplinary capability enabled all work to be done in-house, thereby reducing management complexity