Hunter Water Reservoir Refurbishments

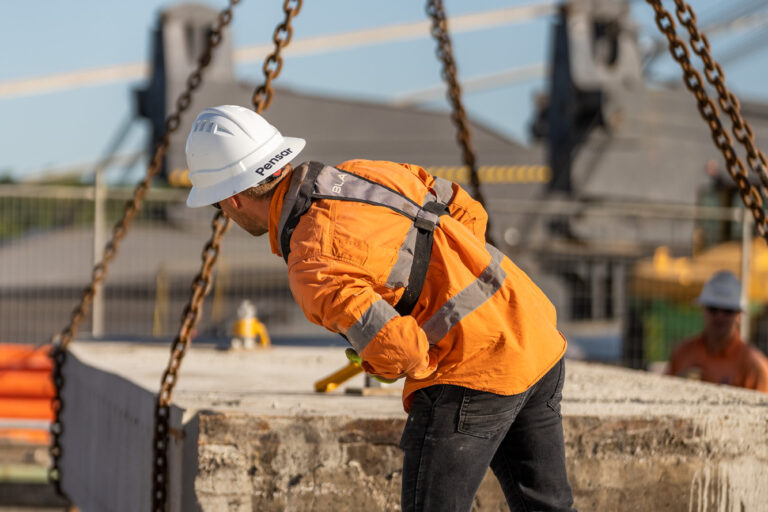

About the project

2021 ACRA Award Winning Project

Three reservoirs, constructed in the 1920s and 30s, were experiencing significant water loss through the wall and floor expansion joints. Pensar was engaged for the refurbishment of one above ground and two partially buried reservoirs.

Location

Multiple Locations, New South Wales

Client & Duration

Hunter Water

April 2019 – December 2019

Project Scope

- The clean and mechanical abrasion of all associated surfaces and joints

- Supply and application of Parchem Nitomortar 903 and WPE110 polyurea membrane system to the wall surface area, floor expansion joint and floor to wall and floor to column joints

- Restoration of distribution surfaces

- Sandblasting and recoating of steel reservoir access platform with Nitocote EP405

- 12-month defects inspection and condition assessment using a remote operated submarine under disinfected conditions

Challenges

- Upon entry it was identified that original construction techniques contributed to the permeability of the walls

- The floor substrate on which polyurea was to be installed was of low strength and achieving undesirable surface adhesion

- The floor and walls contained cracking and voids below the slab

- Initial site inspections revealed challenging conditions including tree roots growing through wall joints, structural corrosion and below ground cracking

- The reservoir walls had experienced a significant loss of fines, reducing cover to reinforcement

- Weather throughout the Winter months impacted the dew point and ambient temperatures

Achievements

- Pensar’s concrete technicians sealed leaks and voids, through which water was escaping, by injecting a hydrophilic expanding injection grout resin

- To increase strength and improve surface adhesion, a floor planer was used

- A penetrating epoxy primer was used to bind and strengthen the substrate while priming for polyurea installation

- For durability and water quality purposes, all internal cracks were sealed through crack injection

- Concrete cover was improved with an epoxy mortar blend render

- Programming and artificial heating allowed works to continue during undesirable weather conditions

- All works were undertaken effectively during a short shutdown period

- 2021 ACRA Award winning project